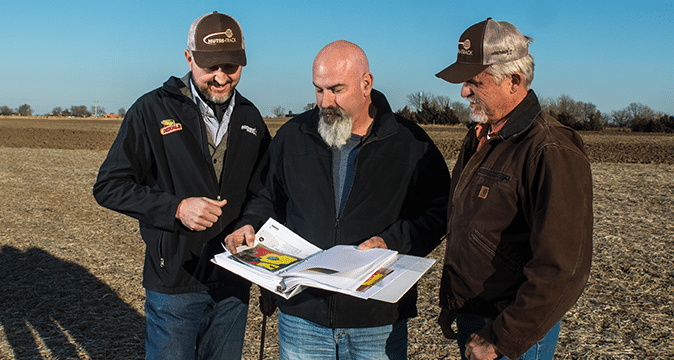

Chuck and Darin Dunlop are cousins and are the fourth generation in their family to farm and the fifth generation is quickly learning the business. Dunlop Farms is made up of 6,800 acres in three southeast Kansas counties, most of which is corn and soybeans. Wheat is occasionally added to the rotation. The Dunlops started working with Jason Sutterby at Ag Choice in 2013. The integration of 4R practices on the farm hasn’t stopped since.

The Dunlops previously used conventional tillage and fertilizer rates based on flat yield goals for nitrogen, phosphorus, and potassium. They now start with 2.5-acre grid soil sampling and analysis to determine nutrient levels, pH, cation exchange capacity (CEC), and organic matter. Nutrient prescriptions are then developed based on soil tests and yield monitoring data and are integrated into a VRT program. Split application of nitrogen, most of it applied in season is now fully in place. In 2016, they conducted variable-rate nitrogen top-dress trials and after evaluation, 100 percent of corn acres are now in a variable-rate nitrogen modeling program.

Nitrogen Use Efficiency (NUE) for the last corn harvest was 0.9 lbs. per bushel, compared to 1.2 lbs. per bushel previously. VRT has helped decrease phosphorous application rates by 15 percent. Soybeans are now 100 percent no-till and corn is minimum-till.

Best Practice Management

- Use nitrogen stabilizer for liquid and dry fertilizer

- Use urease inhibitor to reduce nitrogen loss

- Use nitrification inhibitor to reduce in-field nitrogen loss

- Grid soil sampling

- Variable-rate nutrient application

- Account for nutrient credit from previous year to determine rate

- Use split application of nutrients so plants take them up more efficiently

- Use Adapt-N program for in-season nitrogen management

Phosphorous and potassium only applied in January and February and are immediately incorporated - In-season plant tissue testing

- Foliar application of nutrients

- GPS-precision planting gets the right seed where it needs to go

- GPS-precision nutrient application avoids skips and saves on input costs

- GPS tillage

- Use satellite imaging to help identify yield potential and nutrient management plans